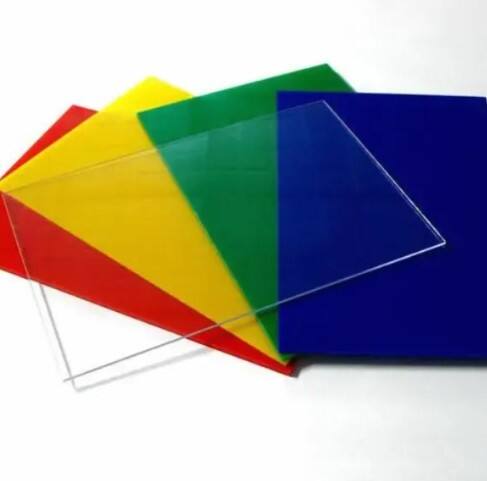

Custom acrylic board fabrication allows you to create versatile and durable solutions for various needs. You can find acrylic boards in signage, furniture, and protective barriers. Their lightweight nature, clarity, and resistance to impact make them ideal for custom projects. This process ensures precision and adaptability for industries requiring tailored designs.

Overview of Acrylic Boards

Acrylic boards are versatile materials that offer a wide range of applications. To better understand their potential, let’s explore their types, properties, and benefits.

Types of Acrylic Boards

You’ll find two main types of acrylic boards: cast and extruded. Cast acrylic boards are made by pouring liquid acrylic into molds, resulting in a high-quality finish and better resistance to scratches. These are ideal for projects requiring precision and durability. On the other hand, extruded acrylic boards are produced by pushing acrylic through a machine, making them more affordable and easier to cut. They work well for projects where cost-efficiency is a priority.

Key Fabrication Techniques

Understanding the key fabrication techniques helps you work effectively with acrylic boards. These methods ensure precision and allow you to achieve professional results.

Cutting Acrylic Boards

Cutting acrylic boards requires the right tools and techniques. You can use a laser cutter for precise and clean edges. For smaller projects, a scoring knife works well. Simply score the surface multiple times and snap the board along the line. If you prefer power tools, a circular saw with a fine-tooth blade ensures smooth cuts. Always secure the board to prevent movement during cutting. Wear safety goggles to protect your eyes from debris.

Bending and Shaping Acrylic Boards

You can bend acrylic boards by applying heat. A strip heater works best for straight bends. Place the board over the heater until it softens, then gently bend it to the desired angle. For more complex shapes, use an oven to heat the entire board evenly. Once pliable, mold it into the shape you need. Allow the board to cool completely to retain its new form.

Joining Acrylic Boards

Joining acrylic boards requires adhesives designed for plastics. Solvent-based adhesives create strong bonds by slightly melting the edges. Apply the adhesive sparingly to avoid visible marks. For larger projects, mechanical fasteners like screws or bolts provide additional support. Drill pilot holes to prevent cracking.

Polishing and Finishing Acrylic Boards

Polishing gives acrylic boards a professional finish. Use sandpaper to smooth rough edges, starting with coarse grit and moving to finer grit. For a glossy finish, buff the edges with a polishing compound and a soft cloth. If you want a crystal-clear surface, consider using a flame polisher. Move the flame evenly across the edges for a smooth result.

Step-by-Step Guide to Fabrication

Planning and Designing Your Project

Start your project by defining its purpose and requirements. Sketch your design on paper or use design software to create a detailed plan. Include dimensions, shapes, and any specific features you want. This step ensures you have a clear vision before working with the acrylic board. Choose the right type of acrylic based on your project’s needs. For example, cast acrylic works well for intricate designs, while extruded acrylic is better for cost-effective solutions. Always measure twice to avoid errors during fabrication.

Cutting and Shaping the Acrylic

Cutting and shaping require precision. Use tools like a laser cutter for intricate designs or a circular saw for straight cuts. Secure the acrylic board firmly to prevent movement. Mark your cutting lines clearly with a ruler and marker. For shaping, heat the acrylic using a strip heater or oven until it becomes pliable. Mold it into the desired form and let it cool completely to maintain its shape. Always wear safety gear to protect yourself during this process.

Assembling and Joining Components

When assembling, align the pieces carefully to ensure a seamless fit. Use solvent-based adhesives for strong bonds. Apply the adhesive sparingly to avoid visible marks. For larger projects, consider using screws or bolts for added stability. Drill pilot holes to prevent cracking. Take your time during this step to achieve a professional finish.

Finishing Touches and Polishing

Polishing enhances the final look of your project. Sand rough edges with sandpaper, starting with coarse grit and progressing to finer grit. For a glossy finish, buff the edges with a polishing compound and a soft cloth. If you want a crystal-clear edge, use a flame polisher. Move the flame evenly across the surface for the best results. Inspect your work to ensure it meets your expectations.

Maintenance and Care Tips

Proper maintenance ensures your acrylic boards remain in excellent condition for years. Follow these tips to keep them looking their best.

Cleaning Acrylic Boards

Regular cleaning prevents dirt and grime from dulling the surface. Use a soft microfiber cloth to wipe away dust. For deeper cleaning, mix lukewarm water with a few drops of mild dish soap. Gently clean the board using a damp cloth. Avoid harsh chemicals like ammonia-based cleaners, as they can damage the surface.

Removing Scratches and Scuffs

Minor scratches and scuffs are common but easy to fix. Start by using a plastic polish or a scratch remover designed for acrylic. Apply a small amount to the affected area and buff it gently with a soft cloth. For deeper scratches, use fine-grit sandpaper. Sand the area lightly, then polish it with a compound to restore clarity.

Long-Term Care for Durability

Protect your acrylic boards from excessive heat and direct sunlight. Prolonged exposure can cause warping or discoloration. Use protective covers or store them in shaded areas when not in use. Handle the boards with care to avoid accidental impacts.

By following these steps, you ensure your acrylic boards remain durable and visually appealing over time.

Custom acrylic board fabrication empowers you to create durable and versatile solutions tailored to your needs. Acrylic boards offer unmatched clarity, strength, and adaptability for countless applications. Their ease of customization makes them ideal for creative projects. Start exploring acrylic fabrication today to bring your ideas to life with precision and style!